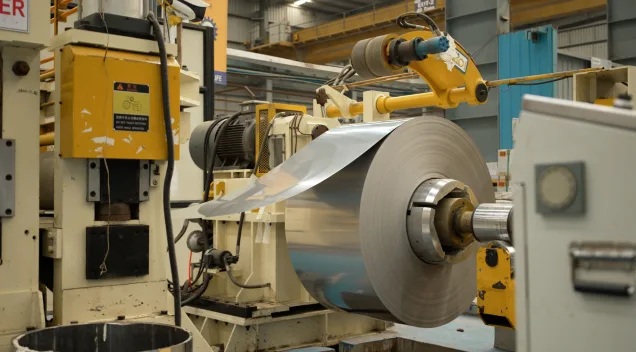

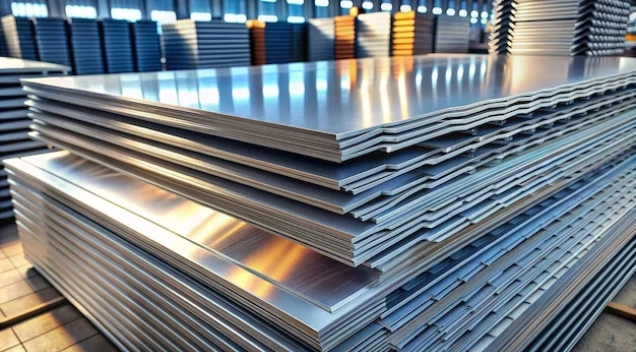

Shree Ramdev Group of Companies, an ISO 9001 and IATF 16949 certified process manufacturer with over 52 years of experience, excels in stainless steel products and services. We specialize in cutting, slitting, and finishing at our advanced Coil Service Station and manufacture a wide range of industrial components and cookware-related products. Our extensive product range and customer-focused approach ensure top-quality, tailored solutions for every client.

In 1972, Mr. Prabhudayal Dharamji Purohit came from a tiny village in Rajasthan all the way to Bombay to fulfill his dream. A man of humble beginnings, Mr. Prabhudayal Purohit was hard pressed for finances but his business acumen and undying spirit led him to conceive, initiate and establish Shree Ramdev Metal Mart, a small retail trading company dealing in utensils, sheets, and pipes.

At Shree Ramdev Group of Companies, we’re always looking for passionate and driven individuals to join our diverse team.

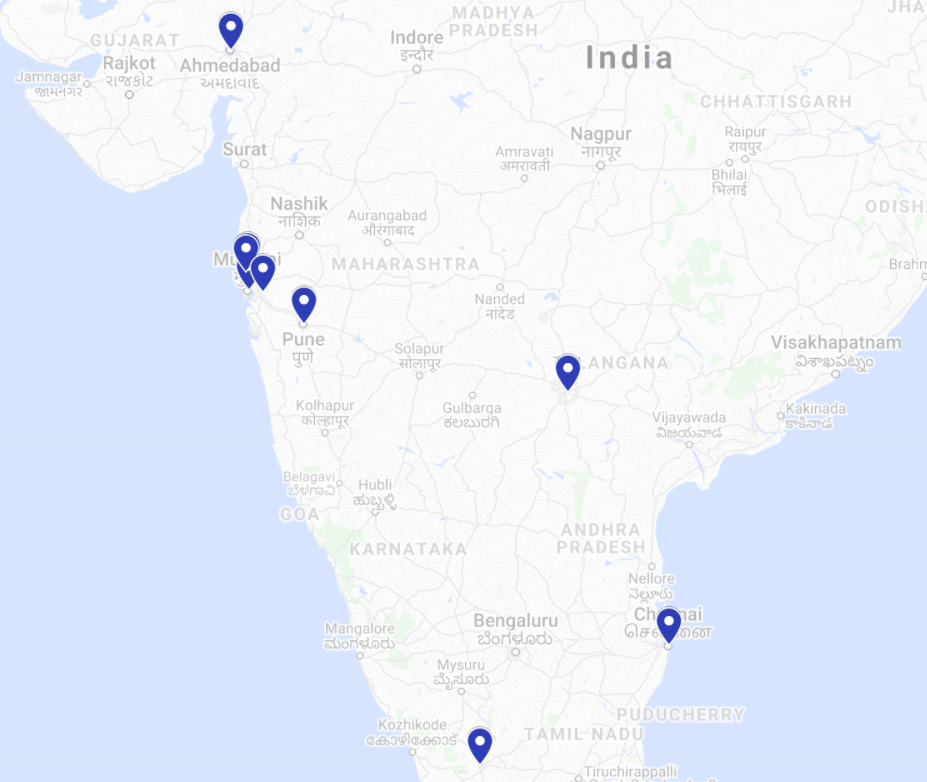

A global leader from India, reputed for being known as Process Manufacturers, Exporters, Importers, Suppliers, Stockist and Traders of superior quality STAINLESS STEEL PRODUCTS and RAW MATERIALS.

Shree Ramdev Group of Companies, an ISO 9001-certified leader, specializes in stainless steel manufacturing, processing, and trading. With cutting-edge services like slitting and finishing, we deliver superior-quality industrial components, cookware, and tailored solutions globally.

WhatsApp us